Dynamic Insert Technology

Dynamic Insert Technology (DIT) is a patented technology that has been developed to further optimize the performance of FAM to automatically and dynamically control pressure on one or multiple surfaces while adjusting for height differences and tilt (compensating most of the tolerances). In this way window or “exposed areas” can be created through (transfer-molding) package encapsulation. This is of particular importance for eg sensors, MEMs, power-, optical- and medical devices.

The same technology has proven to be instrumental in Ag-sintering. Through the ability to automatically and dynamically control pressure on one or multiple surfaces while adjusting for height differences and tilt, very defined and homogeneous pressure can be applied on accurately defined surfaces which is crucial to ensure that the Ag-bond line becomes homogeneous in thickness and density. This ensures good performance and high reliability.

See below an overview of the different configurations supported, tuned to the application requirements:

Our products

Boschman offers two categories of Ag sintering and Film Assisted Molding (FAM) solutions: for R&D, prototyping and low volume production we offer the Semi-automatic, Sinter- en Unistar Innovate series. And for efficient, high quality medium to high volume production the Sinter- en Unistar Auto and Inline series are the best choice.

Sinterstar Innovate series

The most universal semi-automatic sintering system for all your green, lead free die attach technologies. Silver sintering is a new die attach technology offering a void-free and strong bond with high thermal and electrical conductivity. Resulting in high yield and high reliability.

The system is capable to sinter a wide range of different devices, among others led, power, igbt, qfn, clip/heatsinks, thyristor and custom designed power module devices. The Sinterstar Innovate-F-XL excels in offering largest sinter area of 350 x 270 mm and a precise temperature control up to 320 C. Our unique high precision dynamic insert pressure control technologies enables you to sinter multiple dies with different die thicknesses. Resulting in a controlled and predictable bond strength.

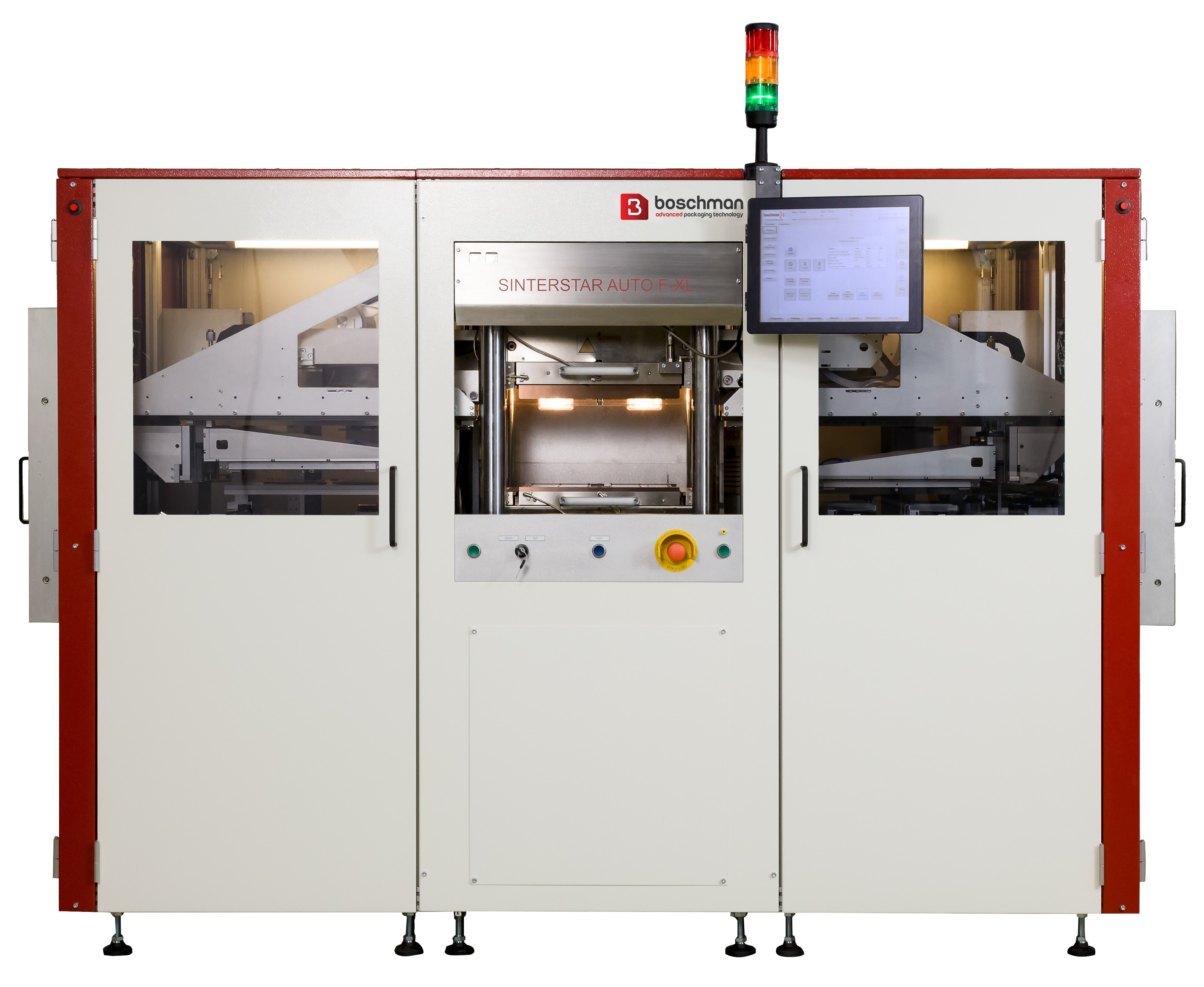

Sinterstar Inline and Sinterstar Auto Series

Our fully automatic Ag sintering systems offer the absolute highest throughput available in the market. Our systems are capable of sintering a wide range of different devices: among others LEDs, Power Devices Clip/heatsinks assemblies, solar (CVP) cells, custom designed power modules and more.

The systems excel in offering the largest sinter area of 350×270 mm, precise process-control and –monitoring, logging large number of key parameters to auto-control the quality with pre-set upper and lower control levels. All our systems can be equipped with a large variety of sintering tool concepts.

Unistar Inline and Unistar auto

Fully automatic 2- or 4-strip Film Assisted Molding system designed for advanced mems, sensors, power, qfn and bga packages. The system can work with lead frames, substrates and ceramic carriers as well as individual modules upto a size of 100×300 mm. Standard equipped with Boschman’s unique and patented double Film Assisted Molding technologies.

Unistar Innovate series

The most universal semi-automatic molding system designed for practically any kind of package. Suitable for package technology research, package development, process optimization, qualification runs and small to medium-sized production volumes. This system can handle test molds, 1-strip molds and 2-strip molds.

Transfer process technology used in this system is identical to the technology used in automated systems. Works with lead frame, substrate and ceramic carriers as well as individual modules. Comes with Film-Assisted Molding technology as standard. Capacity for carriers of up to 75 x 255 mm.

Our other technologies

Boschman (NL)

Boschman (NL)

Advanced packaging technology

Stenograaf 3, 6921 EX Duiven

The Netherlands

T +31 26 319 4900

Boschman (SG)

Boschman (SG)

Advanced packaging technology

No. 3 Kaki Bukit Crescent, #01-01, Singapore 416237

T +65 6743 7188

Boschman (CN)

Boschman (CN)

Advanced packaging technology

No. 188, Zixu Road, Xukou Town, Wuzhong District, Suzhou City, Jiangsu Province, China

中國江苏省苏州市吴中区胥口镇子胥路188号

T +86 188 0918 5028

Contact

E info@boschman.nl

W www.boschman.nl